Industrial systems and equipment can face failure at any point, and in turn, may affect the production or productivity of the business. Timely maintenance can help address these problems to a great extent and make the systems and equipment more efficient. However, failures may still occur and immediate action will be required in the form of rectifying the problems or obtaining necessary spare parts to retain smooth functioning.

In such scenarios, if you are able to identify the possibilities of failures beforehand, then you can take enough preventive measures to avoid them. Predictive maintenance helps you foresee a failure and avoid it from hampering the productivity of a business unit.

What is Predictive Maintenance?

Predictive maintenance is a technique to determine the condition of an equipment to identify maintenance requirements to maximize its performance. Generally, this prediction is directed towards preventing an equipment from future breakdowns, failures, or outages by continuously monitoring data related to performance and efficiency of a given asset. Using predictive maintenance, you can predict when and which equipment needs maintenance.

Role of Predictive Maintenance in Different Industrial Automation Scenarios

In industrial automation, predictive maintenance helps ensure optimum utilization of industrial assets with conditional monitoring of data. Predictive maintenance also plays an important role to detect problems that exist between scheduled inspections. Apart from these, it plays a crucial role in different scenarios as mentioned below:

Scenario 1: Immediate Replacement of Spare Parts

When a certain type of failure occurs, it is difficult to acquire or replace spare parts of the machines and equipment on an immediate basis. This may result in production or process halt. Predictive maintenance helps organizations prevent occurrences of such scenarios by continuously monitoring the condition of machines and identifying the time to replace spare parts.

Scenario 2: Timely Repairing of Machines

Predictive maintenance also plays an important role in saving the costs of repairing equipment and servicing of machines by identifying timely repairs and maintenance. It can be highly beneficial in scenarios where these assets require fixes and routine servicing to be identified, which if not done on a timely basis can lead to machine breakdowns.

Scenario 3: Hazardous Outage Occurrences

Predictive maintenance also helps reduce risks and harm caused to manpower and resources in certain hazardous outages by identifying potential breakdowns/incidents in advance, which otherwise can turn out to be a hindrance for the organization as a whole.

Scenario 4: Time-consuming Rectifications

Certain outages can be time-consuming and require a lot of man-hours to rectify the problems. With predictive maintenance, organizations can prepare with the right resources and course of actions in advance and save time and efforts to recover from chaos.

Scenario 5: Efficient Equipment

Predictive maintenance is also important for maintaining the efficiency of equipment and systems of production in order to meet the required production targets.

Apart from the above scenarios, you or your organization can implement predictive maintenance in a variety of cases based on the requirements and defined objective utilizing various techniques.

A Few Techniques of Incorporating Predictive Maintenance in Industrial Automation Solutions

When it comes to utilizing predictive maintenance in industrial automation, you can follow the below techniques:

Thermography

This technique is used to detect any mismatch in the work of equipment by measuring its temperature during the inspection time. Thermography uses infrared instruments like line scanners, infrared thermometers etc. in which temperature is fixed for the equipment and is monitored for changes in the temperature. Based on the variations noticed in temperature of a given equipment, one can predict the maintenance requirements.

Thermography is useful to measure bearing temperatures in motors and to identify leakages in vessels. It also helps detect problems in gearboxes, transmissions and steam lines that rely on heat transfers.

Ultrasound

This technique uses airborne ultrasound instruments which translate high-frequency sounds that is 20 kHz produced by steams or air leaks into audible which can be heard through headphones. The Ultrasonic translator then converts the sounds into decibel unit which can be seen on the display panel, and according to the value displayed you will be able to predict the maintenance requirements in machines.

Ultrasound technique gives information about air leakage detection in compressed air, mechanical detection in bearings gears and steam trap leakage. It is also the best suitable technique for low-speed RPM machines.

Vibration Analysis

Vibration analysis is applied to the machines with moving parts which generate vibration. Vibration can be detected using transducer. This device contains accelerometers for detecting vibration which is fixed into the machine. Transducers then transform mechanical energy into electric signals and send it to a data gathering device which stores data. After that, if higher vibration is identified, it is then concluded that the equipment requires urgent maintenance or you can compare the value with baseline data.

This technique is useful to point out problems like damages, looseness, misalignment, etc. in equipment. The method uses a Balancing equipment which assists in correcting machinery problems. This technique is highly useful for all ranges of RPM machines.

Oil Analysis

This technique is used to find out metallic particles in the oil. Due to the heat of hydrocarbons, viscosity of oil increase. By using Viscometer, you can measure the viscosity of the oil and determine whether the oil change is required or not.

Similar to this, to find out the ferrous metal content in oil, Magnetometer is used, which measures the mass of ferrous material in a sample of oil and displays it as a particle quantifier index. When particle quantifier results are Low and Fe is high, it indicates that particles are less than 10 µm. When the particle quantifier results are high and Fe is high, it indicates that majority of the particles are less than 10 µm.

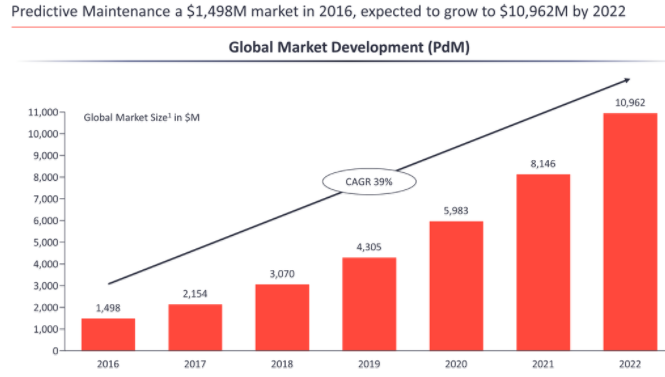

With the usage and implications of predictive maintenance, it is expected that the market of predictive maintenance will emerge to a great extent between the period 2016 and 2022.

According to a recent research conducted by IoT Analytics, predictive maintenance is all set to seize the capture the market growth. The report forecasts a compound annual growth rate (CAGR) for Predictive Maintenance of 39% over the timeframe of 2016-2022, with annual technology spending reaching US$10.96 Billion by 2022. These numbers are based on the Predictive Maintenance related revenue of leading technology companies in the field, across 13 industries and 7 technology areas.

Caption: Predictive Maintenance Market Report 2016-2022 by IoT Analytics

Certainly, predictive maintenance comes with a handful of benefits for industrial automation. Below listed are a few benefits that organizations leverage by implementing predictive maintenance in their processes.

Benefits of Utilizing Predictive Maintenance

- Reduces time of repairing and labor cost if the maintenance is done as per the planned schedule.

- Increases productivity and process quality before actual failure by pointing out the faults in the maintenance process.

- Expands equipment lifespan and efficiency with regular maintenance of machines as per defined intervals in the predictive maintenance calendar.

- Reduces costs of replacement since both minor and major repairs are identified beforehand and necessary actions are taken before the actual failure occurs.

Considering the above benefits and implications of predictive maintenance, it is highly advisable for organizations that deal with heavy machinery and production units to employ predictive maintenance.

Emerging Trends in Predictive Maintenance in Industrial Automation Predictive maintenance in industrial automation is experiencing rapid evolution, driven by technological advancements.

Here are some key trends:

- AI and Machine Learning: Integration of AI and machine learning enhances predictive capabilities, enabling more accurate equipment failure predictions.

- Edge Computing: Real-time analysis is facilitated through edge computing, reducing latency and enabling immediate anomaly detection.

- IoT Integration: IoT devices and sensors provides real-time data helps improve predictive maintenance accuracy.

- Digital Twins: Virtual replicas of assets allow for precise predictive modeling and testing before implementing maintenance strategies.

- Prescriptive Maintenance: Beyond predictions, prescriptive maintenance offers actionable recommendations for maintenance tasks.

- Blockchain Security: Blockchain enhances data security and transparency in predictive maintenance records.

- Augmented Reality (AR): AR assists technicians in diagnosing and repairing equipment, improving efficiency.

- Energy Efficiency: Predictive maintenance evolves to consider energy-efficient scheduling.

- Cloud-Based Solutions: Cloud computing enables centralized data storage and analysis for more accessible predictive maintenance.

- Predictive Maintenance as a Service (PMaaS): PMaaS providers offer scalable and customizable solutions for easier adoption. These trends reflect the ongoing transformation of predictive maintenance, enhancing equipment reliability and reducing downtime in industrial automation.

eInfochips helps in developing analytical and engineering solutions for domains like Industrial Automation, Energy Generation Equipment, and Actuation Systems. It also has expertise in developing server-based performance analytics and predictive maintenance solutions using engineering design data, logs, and records.

Looking for smart predictive maintenance solutions to drive continuous monitoring and connectivity of industrial devices and equipment. Contact us now!