Introduction

Embedded systems were first used in 1960 for building Apollo Guidance Computer. It was the first modern embedded system, which was used for navigation and control of the spacecraft. It helped astronauts collect real-time flight data and automatically control its functions. The integrated circuits (ICs) were first used in Apollo Flight Computer. The journey of embedded system from Apollo Guidance Computer to the Connected Smart Devices is fascinating. Embedded systems are the key enablers for smart devices across the world.

In today’s dynamic technology-driven business environment, we are surrounded by intelligent devices. These devices are becoming smart enough to capture, record, detect and even perform analytics at the edge.

The growing demand for customized solutions, ease of use, remote monitoring and control is giving rise to innovation and adoption of disruptive technologies.

The electronic design and manufacturing service industries are experiencing a major turnaround with a considerable surge in consumer adoption for smart solutions. For example, the demand for automotive infotainment devices have transformed the electronic device design & manufacturing segment and brought innovation in PCB design with the use of Electronic Design Automation (EDA).

According to Research and Market, Electronic Design Automation (EDA) market is expected to grow $28.27 billion by 2027 at a CAGR of 12.0%.

EDA comprises of multiple tools and applications. Computer-aided engineering (CAE), an EDA tool, helps to enhance the analysis of the objects. CAE is the first choice as it helps in lowering simulation cost and design time by minimizing errors and improving system performance.

It is not adequate to have a more advanced product, a lower-priced product, or a groundbreaking product. Instead, balancing all of these attributes in each product is critical to winning business. To succeed as a product company, you must continually innovate while maintaining competitive quality, price, and service.

Today, technology-based businesses are more inclined towards quality-driven device engineering services. The growing use of electronic devices, communication technologies, the convergence of digital technologies and rapidly changing consumer demands are driving the market.

According to Markets and Markets, by 2021, Device engineering services market will be about 1 trillion dollars at a CAGR of 8.2%.

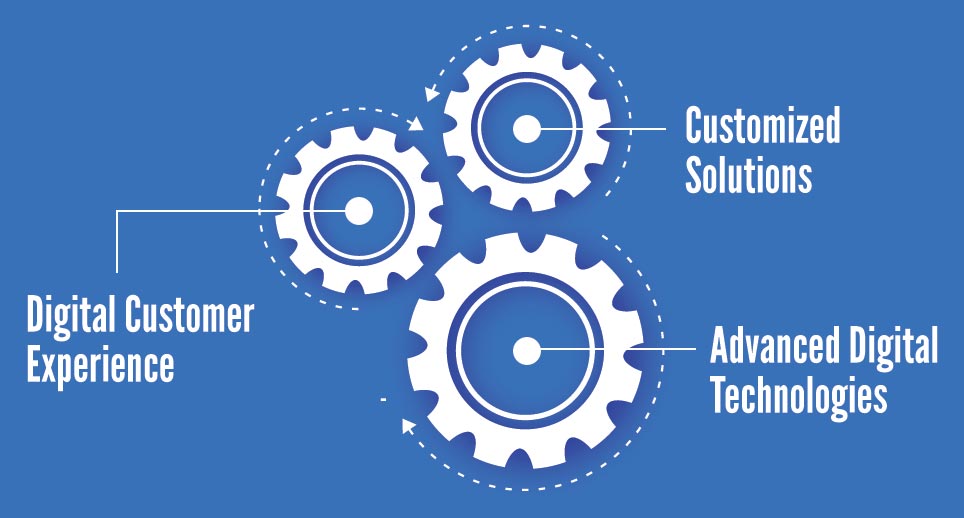

As businesses around the world are looking for smarter customized solutions that can integrate digital technologies, product design and development becomes all the more complex. The hardware design and engineering services companies are playing a crucial role in keeping pace with the evolving technologies and increasing customer preferences.

To provide better digital customer experience, Device Engineering Services (DES) are focusing on creating a sustainable quality products by leveraging digital technologies like IoT, Artificial Intelligence, Machine Learning, Cloud Computing, Big Data, and Analytics.

Read on to know more about why and when businesses need DES, challenges associated with product design & development, how DES works, how to choose your electronic partner, and many more.

Why Companies are Outsourcing DES?

Several factors, such as rising consumer demands for advanced digital devices with low time to market and low cost to market are the reason behind the rapid growth of Device engineering companies. The device engineering service companies are helping almost all industries with digital transformation. Verticals such as healthcare, aerospace, home automation, automotive, consumer electronics, telecom, semiconductors, and many more are driving the hardware design and engineering services market.

What is Device Engineering? ―Device engineering is nothing but a set of techniques that uses various hardware, software embedded systems, and IT solutions to design and develop a complete product. The device engineering company design and developed the product based on the specific set of problems formulated by the client. Check out, why would device engineering services are needed?

The device engineering services company not only helps to reduce costs, but also help businesses become more competitive and reliable in the global digital market. DES can help companies to

- Get an experienced digital partner that can independently develop smart products.

- Stay focused on their core competencies by leaving behind the product development job to the DES Company.

- Gain exposure to newer technologies for innovation that was not possible due to time and workforce limitations.

- Be agile and more productive.

- Enhance system interoperability and evolution.

- Get expert guidance, product design, and engineering.

- Leverage new age development model and automated testing practices

- Provide digital customer experiences by leveraging advanced technologies.

Key Drivers of DES

Device engineering service providers are gaining importance because they can design and develop products that are smarter, faster, and reliable. The primary and critical drivers of DES are lower time to market, lower cost to market, digital capabilities, and continuous innovation. The device engineering firms do not only decrease the design & development time but also help to reduce operational costs.

Lower Time to market

Time to market is crucial for organizations to deliver products on time. With the advent of digital technologies, things are moving faster than earlier. The market is demanding more superior and technology integrated products with quality and speed. The goal of a DES is to not only deliver a quality product but also at a faster rate.

Through world-class innovation and agile product development life cycles, DES is helping businesses to launch products on schedule and hence decreasing the time to market.

Lower Cost to Market

Another critical requirement that each organization looking for is ―lower cost to market. DES companies with their domain expertise and continuous customer support, helps businesses to reduce operating and maintenance costs. Companies can now rely on the support provided by DES.

Digital Capabilities

Rapid need for smart consumer electronics coupled with the integration of cutting edge technologies such as powerful AI cameras, high-resolution video recording, intelligent displays, and fingerprint scanning are the buzzwords today. The businesses are adopting various practices to transform legacy devices into smart devices, to get them started, , they are outsourcing device engineering service companies. This is why device engineering companies are proving to be essential today.

Continuous Innovation

Businesses are required to be innovative to fulfill the changing consumer demand for smarter products. The focus should be on core hardware design skills and integration of digital technologies. With continuous innovation, businesses can deliver customer-specific flexible solutions.

Device Design and Engineering Challenges

Product designing is becoming more complicated with the integration of digital technologies like IoT, Cloud, AI/ML, and Big Data Analytics. The IoT based circuit designing is in demand that can connect devices on a single network. Businesses are moving from cloud computing to the critical edge computing, and this is why flexible product designing is gaining much importance now.

The companies need to be ready to overcome the product design and development challenges coming their way, we have collected a few of the critical challenges companies are facing

High Power Dissipation in circuits

As the number of devices are getting connected using IoT, the power consumption for them is also increasing. The devices are connected to the gateway to a single network. With an increase in gate density, the power dissipation through the transistors increases, which requires higher power density.

The data transfer through the connected IoT devices is most expensive as it involves the connection through Wi-Fi, Bluetooth, Cellular, and so on.

The challenge is to reduce the amount of power consumed during the data transfer from the devices to the cloud. Device engineering services are helping businesses with this by designing efficient system architecture.

Technical Support from Silicon OEM

DES often encounters difficulty when designing any critical part using silicon devices and to overcome this, they need a continuous support from the original equipment manufacturer. Getting a technical support from the silicon OEM is a daunting task. This not only delays the project completion time but also incurs more cost. Make sure that the DES and silicon OEM have clear communication between them and silicon OEM are available 24/7 for any technical support.

Meeting Performance Criteria

Meeting the expectations in design and the actual product is sometimes difficult to attain as the designing becomes more complicated due to critical requirements. Hence device design feasibility plays a crucial role during the early stages of project management. During the feasibility analysis, all design and engineering aspects are checked for meeting the performance criteria. DES uses Design for Manufacturing and Assembly (DFMA) and Design for Testability (DFT) approach to develop a hardware product that is easy to design and apply manufacturing test.

Data Security

Security is another challenge in device engineering, as all devices are connected through the network. It becomes essential to take security as a priority while designing software as well as hardware of a typical system.

DES takes care of security concern from prototype to development phase by securing the embedded systems with a cryptographic algorithm. It involves the use of well-defined mathematical instructions that encrypt the data sent & received by the connected devices.

Size Constraints

Size limitation is one of the significant challenges that the engineer faces while designing and developing devices. Sometimes in low geometry design, the components need to be placed in very small spaces so as to include all the functionalities in a compact design.. DES carefully takes care of the sizing issue during the designing phase itself such that the sizing problem should not occur and device functions appropriately.

Testing

Once the product is developed, it is tested for performance, consistency, and accuracy. Product testing and validation are mandatory in product hardware design and engineering. Organizations are facing challenges in performing accurate and faster product testing. Device engineering services companies are using machine learning and artificial intelligence to perform automatic software and hardware testing. This not only helps in reducing time to launch the product in the market but also reduces the errors and improves the product performance.

Regulatory Compliance and Certifications

This is one of the significant challenges that companies face during designing and engineering of a device. The designers have to structure hardware based on the customer requirement according to applicable compliances. This becomes more difficult when there is any critical requirements and meeting compliances becomes even tricky. DES with their core experiences and capabilities helps the companies to meet customer requirement with required compliances.

How to Choose Your Device Engineering Partner?

Selecting a hardware design and engineering services partner for device development can be a daunting task. From design, development, testing, to deployment, and sustenance, you need to consider all the aspects of device life cycle before choosing your electronic partner.

Look at some essentials while selecting the right electronic partner for successful hardware design and engineering.

Domain Experience and Expertise

While selecting the device engineering service provider, your priority should be looking out for a company that is a pure play hardware design engineering company and has enough experience in handling critical device engineering projects . It is essential to outsource to a core device engineering company having core technical expertise, that acts as a one-stop shop and has a vast experience in delivering the product with the utmost quality.

Before deciding on electronic partner ensure their digital capabilities, work culture, core values, technical expertise, market value, and ability to deliver a sustainable quality product.

Product Design Capabilities

The device engineering company must have ample design resources and skills in digital technologies so that they can provide product design that meets the your requirements and accommodates all the desired functionalities. The DES should use design thinking approach for designing smart devices. Design thinking is a customer-centric approach for problem-solving. It allows a blend of technology and business to cater to specific customer requirements during the product design stage.

For a better user experience companies are outsourcing electronic partners that are embedding design thinking methodology. Apart from the requirements, the device engineering partner must offer an array of services, including agile project management techniques.

Project Management

It is another essential aspect you should be looking in your device engineering partner. During research find out what project management technique the DES is using to execute their projects. Also, ensure that the communication among various teams of DES is transparent. It is excellent if the DES is using agile model for project designing and engineering practices. Agile methodology not only reduces the time of project completion but also improves the quality of end product.

Regulatory Compliance

Delivering quality product with all regulatory compliance is a daunting task. The hardware design firm you are about to outsource should adhere to the latest electronic design and manufacturing standards. They should also understand the regulatory compliances well and keep that in mind while working on any of the product designs.

Certifications

Certification is another aspect that is very important in hardware designs. It demonstrates that a company adheres national and international standards of electronics design and manufacturing industries. This influence the durability, reliability, and quality of the services that they provide as well as the products that they make for their clients. Ensure that the partner is able to provide you continuous support with necessary documentation when the device is sent for certification.

Technology and Resources

The tools, machinery, and technologies the device engineering service company is using should be best in the marketplace if you want to get a competitive edge over your competitors. Partnering with a company that leverages the latest technology and tools makes you capable of delivering smarter solutions.

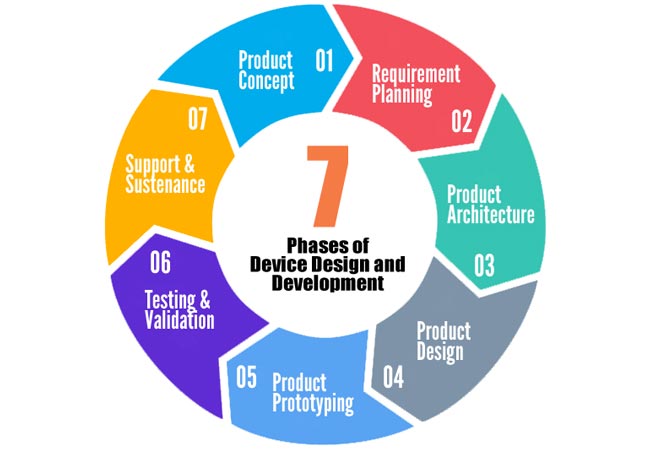

7 Phases of Device Design and Development

1. Product Concept

This is the first stage, which involves conceiving the idea and developing a concept. Ideation is one of the most foundational parts of every device engineering project. The hardware design and engineering company work on conceptualization, requirement planning, and finalizing the product concept.

2. Requirement Gathering & Feasibility Study

Collect customer requirement and document this in hardware & software design specification document. Further, the idea is scrutinized, check for feasibility, and decide whether to go ahead or not.

3. System Architecture

The system architecture should define features properties and characteristics of the product. The hardware, software, and other system components constitute the system architecture.

4. Hardware Design and Development

Hardware designing includes part selection, layout design, BOM preparation, and product manufacturing. Once the hardware manufacturing is finished, it is integrated with firmware and software.

5. Product Prototyping

Computer-aided engineering systems are used to create a fully functional prototype of the product. The prototype is tested for required product characteristics and features. On successful check of performance and accuracy, the product goes for testing and validation.

6. Testing & Validation

Once manufactured the product go to quality analysis to assure that there is no issue. Any upset occurs in the testing and validation phase are addressed by the design and production team. After successful testing and validations, the product is released into the market.

7. Product Support and Sustenance

The device development journey does not stop here. Once the product is live timely updates and enhancements are sent. Product support teams help during any upset with the product. If any bug or problem occurred, assistance is provided by DES for a specific period.

Are you looking to outsource a device engineering company?

eInfochips is a one-stop solution for all your device design and engineering needs. eInfochips maps the entire journey of its clients in the product lifecycle, all the way from design thinking at conceptualization to product design & development to verification & validation, and from IoT integration of devices to Cloud & Big data services to Manufacturing & Sustenance.

Why eInfochips?

- End to End Device Engineering Services Company

- 20+ years of experience in hardware design services

- Expertise in designing embedded systems

- Modern product design and testing capabilities

- Expertise in device IT-OT integration

- Agile project methodology

- Provide all levels of compliance and certifications

- Provide platform partnerships

See how eInfochips is helping the businesses with device design and engineering services.

Device Engineering Success Story

- IoT enabled blender operating system for real-time access to blender data, including blender screen content, devices, and diagnostics based on predictive analytics. The IoT solution improved the reliability of the blender and enabled real-time access to the blender data. This remote based IoT platform helps in controlling appliances from anywhere at any time.

- OPKIX camera is a compact, thoughtfully designed hardware & software solution that allows users to record, edit, and share videos. It is a wearable camera that integrates seamlessly with smartphones, enabling users to instantly capture point-of-view (POV) 1080p high definition (HD) video content without removing the paired smartphone from their pocket. The lightweight and long-lasting video device are ideal for applications such as coaching, medical applications, drones, media & entertainment, and sports.

Conclusion

With a growing need for personalized smart electronic devices, the device engineering services companies are gaining a lot more importance in the market. Though the device engineering term is new in the technology world, it has acquired much impetus helping businesses to accelerate operations and serve even better. As technology is transforming at a rapid pace and with this business has to, and to fulfill customer demands for smarter products and integrated digital technologies, you should outsource a device engineering and services firm. To speak to our Device Engineering experts, please contact us today.