Machine Vision systems are finding increased traction in various fields, especially in the realm of industrial automation. They use image capture and processing technologies for visual inspection and monitoring and involve a number of engineering disciplines including optics, computer science, industrial automation and mechanical engineering.

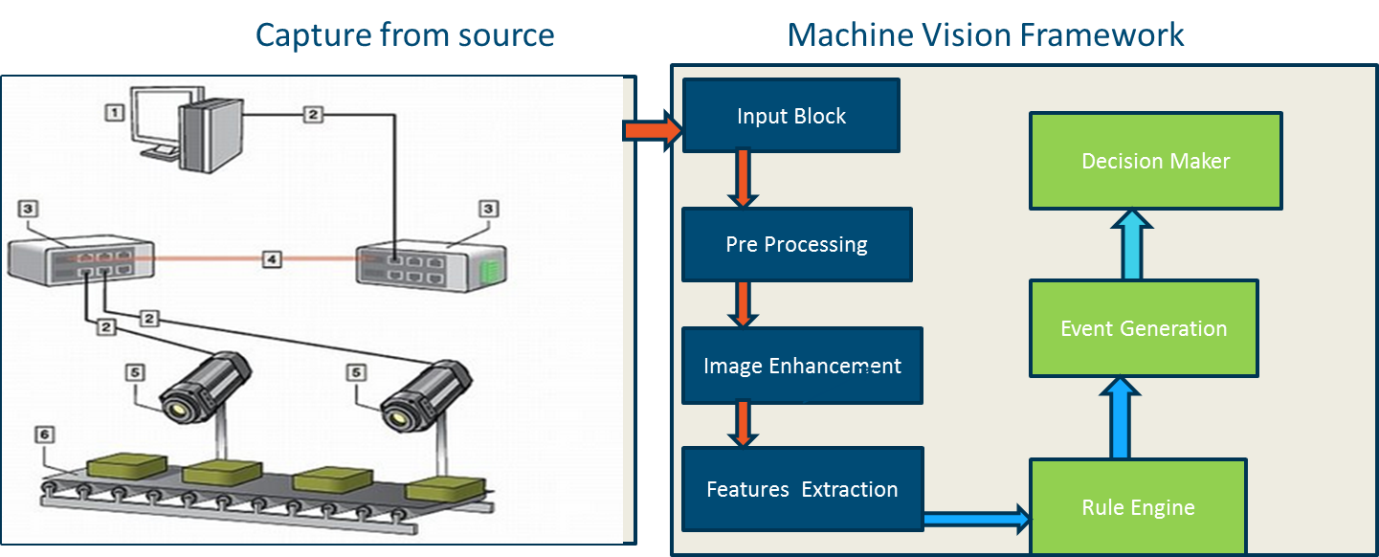

The following is a block diagram of a typical machine vision system:

By definition, any system which involves inputs, processing and output qualify as a machine vision system. In this, inputs are the objects being analyzed/tracked under controlled conditions. The processing mainly involves image processing and vision-based algorithms and outputs typically are the analysis of the captured images and decision-making parameters based on that.

Why this trend is here to stay?

With the huge adoption of automation across industries, the importance of having a fully automated inspection and monitoring system has grown manifold. In addition, drone-based monitoring and robotics are fields where machine vision along with machine learning has been adding tremendous value.

The primary reasons that substantiate the longevity of this trend are as follows:

- Effective monitoring in mass production facilities:

- Wide industry coverage right from automotive to semiconductors to heavy machinery

- Minimization of human efforts and optimized machine-based process monitoring

- Flawless defect detection in parallel to production with a feedback loop to control process

- Value additions through 3D visualization effect:

- 3D visualization effect in monitoring not only solves the purpose of the complete surficial inspection of the product but also eases the process with no human intervention

- This can be achieved through multiple ways including 3D rotating camera, image stitching from multiple cameras as well as rotating platform wherever it makes sense logistically

Applications of Machine Vision in Industrial Automation

Though machine vision has multitudes of applications across industries, a few important ones are listed below:

- Areas of application

- Defect Detection

- Process Monitoring

- Quality Assurance

- Packaging

- Warehouse monitoring and factory floor management

- Industries of application: Top 6 industries that find application for machine vision systems are listed below. In fact, 77% of machine vision solutions are expected to be covered within these industries!

- Automotive: 20%

- Pharmaceuticals: 15.8%

- Industrial Machinery: 41.3%

- Foods and Beverages: 13.3%

- Packaging: 10%

- Semiconductors: 10%

- Heavy Machinery: 8%

Other industries which are fast catching up are agriculture, transit security and

Challenges of adopting machine vision

Machine vision, despite its numerous business, benefits still remains to be utilized to its best potential. The current hurdles facing are:

- Image processing algorithms, which are the prime driving force of the machine vision systems, have still a lot to evolve.

- Each and every setup where machine visions system need to be deployed vary from one another and the solutions have to be customized in their own specific way. Hence, with no generalization and minimal reusability, monetization stands to be the biggest challenge.

Implementing a machine vision system requires technology skills in camera design and building automation solutions, embedded design, algorithm development and mechanical engineering, Considering the exponential growth potential and at the same time, understanding the above challenges it is really important to have an expert innovation partner to venture into this space further. At eInfochips, we have implemented machine vision systems for our clients across various industries. For more information, email us at marketkng@einfochips.com