If recent news stories from the Chinese stock bubble are any indication, investors are no longer doubting what they had already suspected before – economic growth in emerging markets (e.g. BRICS) has considerably slowed down, and is performing way below market expectations. Low output turnover, capital outflows, market turmoil and increasing competition have become the order of the day.

To sustain and grow in emerging markets, original equipment manufacturers (OEMs) need to revisit their future growth strategy. In many cases, it has been found that products developed market may not always be the best fit for developing ones (doesn’t apply to Apple iPhones though – they’re awesome, everywhere you go!). Customers in developing markets like India demand similar feature sets at lower price points much more often compared to their counterparts in developed countries.

The biggest conundrum OEMs want to answer is this – is it possible to replicate say, 90% features of an established product at just 50% of previous cost?

Introducing Value engineering, a time-tested engineering methodology which helps corporations reduce costs but without compromising on the value attached with brands. The basic difference between value engineering approach and a simple cost reduction approach is the emphasis on function. Value engineering analyzes all functions of a product with an aim to achieve them at the lowest possible cost.

Value Engineering Approach

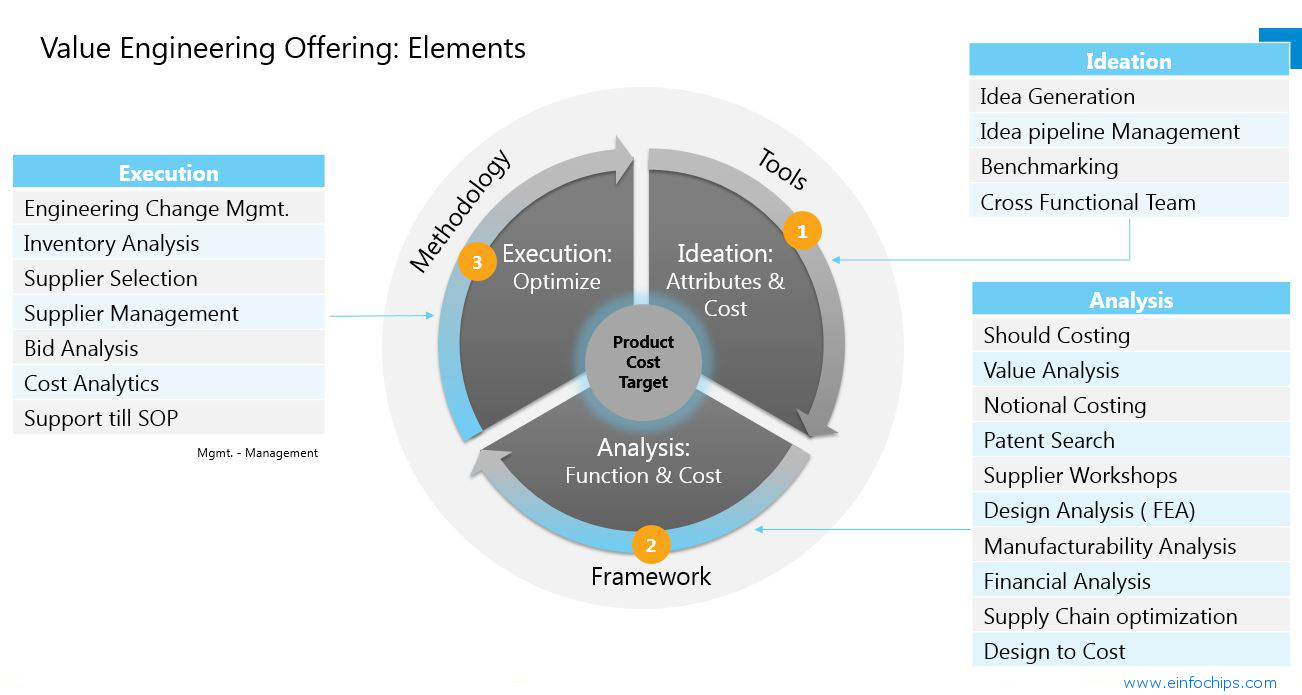

The first step in value engineering is to analyze the exact functions of a product in order to generate ideas. It is followed by evaluating a range of cost-effective options to achieve those specific functions. With all visible data at hand, it is left up to product managers to select the most cost-effective options while maintaining critical elements that comprise value, such as quality, reliability and maintainability. Here’s a simple enumeration of the three stages:

- Ideation: Idea generation, idea pipeline management, benchmarking against competition, cross-functional team formation for further analysis

- Analysis: Value analysis, notional costing, patent search, supplier workshops, design analysis, financial analysis, supply chain optimization, design to cost

- Execution: Engineering change management, inventory analysis, supplier selection, supplier management, cost analytics, production support

Phase-gate model for Value Engineering Process

Ideation, analysis & execution are the three stages of a value engineering process. This Process is divided into stages, separated by gates. At each gate, the continuance of the process is decided by a set of criteria. The final decision is based on the fulfillment of criteria. This process helps identify problems and assess progress before the entire product is value engineered. This model reduces complexity of a large and innovation limiting process into a simple rule-based approach and thereby enables building a solid business case.

Phase-Gate model of value engineering is the solution for emerging markets challenges of product design

This model of value engineering can enable OEMs to successfully design & developed products for emerging markets. To give an example, surveillance camera makers are approaching eInfochips for developing camera with 90% features common in developed markets but at 50% cost. In the ideation stage, complete teardown study of camera available in market is completed along with a list of available feature. Then in the analysis stage, feature vs cost matrix is prepared and based on the end user need of the emerging market, the features are selected. At the final stage of execution, prototype of the camera is developed and field tested. After approval from customer, the actual camera is developed and manufactured which has 90% of the features of similar camera in developed market but only at 50% cost.