Have you ever noticed that most of the technology and electronics we use today would not be possible without the use of PCBs? Be it a medical device that monitors vitals or a smartphone – they all contain PCBs at their core. PCBs help reduce the size of electronic products, making them cost effective. Over time, PCB manufacturers have also improved to keep up with the surging demand for the latest, faster, and more complex electronic circuitry. With the growing use of applications such as robotics, Internet of Things (IoT), and Artificial Intelligence (AI) in our daily lives, the demand for electronic devices has also increased. This indicates that the future of PCBs is bright and that the Printed Circuit Board technology will continue to strengthen.

In fact, according to the Future Market Insight report, the global PCB design market was valued at around US$ 3 bn in 2022, registering a growth of 12.7%. By 2029, the market is expected to grow at a CAGR of 14.9% and reach US$ 7.92 bn in valuation.

Printed Circuit Boards: What Are They?

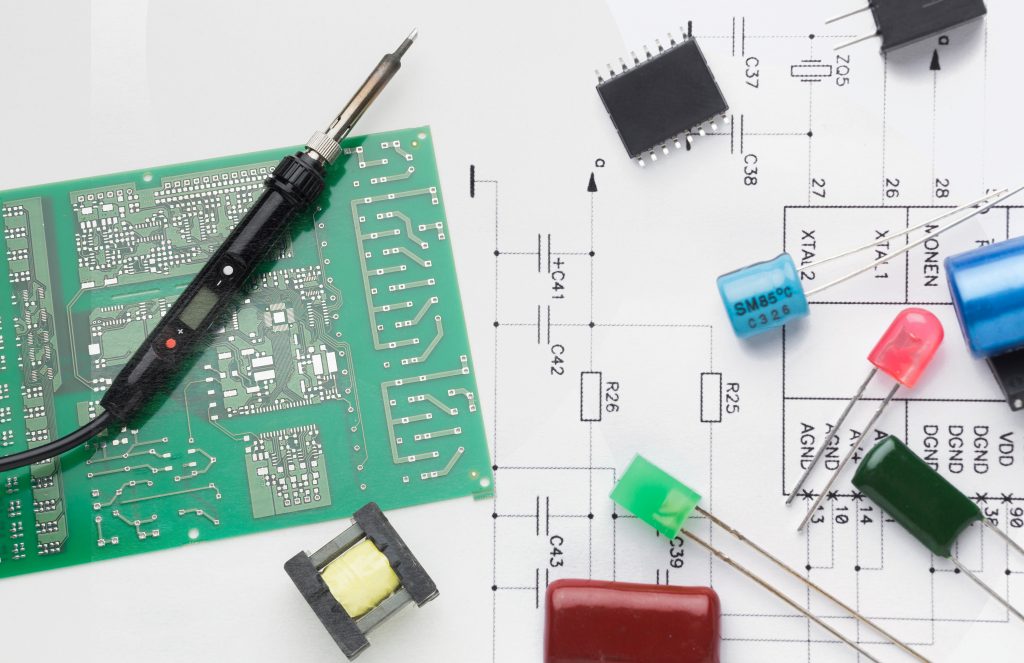

Before the advent of PCBs, circuits were constructed using point-to-point wiring, which was laborious and difficult. PCBs are sometimes referred to by other names, such as “printed wiring boards” or “printed wiring cards”. Wire junctions and short circuits often fail due to wire insulation aging and cracking.

A breakthrough came with the development of wire wrapping that creates an extremely durable and easy-to-change gas-tight connection by wrapping small gauge wires around posts. It was only due to this innovation that electronic components became smaller and econmical as vacuum tubes and relays were replaced by silicon and integrated circuits. As electronic products became more prevalent in consumer goods, manufacturers sought better solutions to reduce their size and manufacturing costs. Thus, the PCB emerged.

Modern PCB Design Best Practices

Use a uniform polygon and grid system

To prevent PCB design failures, it’s important to use a consistent polygon and grid system. While it may be tempting to work with multiple grids or polygon shapes, doing so can increase complexity and cause polygon-fill issues. By adhering to spacing guidelines and keeping trace lengths short and direct, you can prevent issues such as shorts, Electromagnetic Interference (EMI), heat dissipation, and ground faults. It’s also important to keep your components grouped on your grid and avoid 90° bends in traces, which can easily result in shorts. Instead, stick to direct and short routes and opt for gentle 45° turns in traces. Keeping loops small reduces inductance and HF voltage spikes.

Silk screening in PCB Design

When it comes to PCB design, silk screening is a crucial factor to consider, despite not being directly related to the board’s function. Properly implementing silk screening can enhance the manufacturing, testing, servicing, and overall usability of the board. Even if the annotations on the silkscreen layer are hidden under components, they still serve their purpose. In fact, going through the process of labeling on the silkscreen layer may even reveal design flaws that were previously overlooked. Using silkscreen on both sides of the board can help streamline the production process and improve the overall quality of life for both the designer and the end user. Essentially, silk screening is a quality-of-life decision that can benefit everyone involved in the board’s lifecycle.

Effective Power and Grounding in PCB Design

To effectively power and ground a PCB design, copper planes connected to the power and ground connections respectively, are crucial. These planes, known as power planes and ground planes, provide many benefits for the overall design. However, it’s important to note that only PCBs with four or more layers can accommodate power planes.

The use of power planes can yield significant returns on your investment, including shorter paths, improved circuit decoupling, and increased current carrying capacity. By contrast, traces have limited current carrying and heat capacity, meaning that heat builds up more quickly and results in greater resistance in a smaller area. Power planes also help to lower temperatures, reduce wasted electricity, and improve overall function.

Another convenient feature of power planes is their ability to act as decoupling capacitors when vias are used to connect them to the signal layer. This helps to reduce unwanted noise and interference from propagating throughout the PCB design. Overall, the use of power and ground planes can greatly enhance the performance and reliability of a PCB design.

Selecting the Right PCB Design Software for Successful Projects

When it comes to PCB design, the software you use can play a crucial role in the success of your project. While free versions of software may be available for beginners, industry-standard software is necessary for professional work. Some of the top PCB design software used by professionals include Altium Designer, Solidworks PCB, and Autodesk Eagle. While these are not the only options available, they are widely used in the PCB design field. Additionally, Autodesk Eagle offers free licensing for personal use.

Regardless of which software you choose, it’s important to ensure that it can generate all the necessary PCB layout files, including Gerber files or ODB++. Other essential files include Centroid or “Pick and Place”, Bill of Materials (BOM), special requirements (ReadMe text or PDF), and Assembly Drawings (PDF filetype). These files are typically the minimum requirement, but additional files may be needed depending on the product and client specifications. Ultimately, choosing the right software is crucial for creating a successful PCB design project.

Our end-to-end product design engineering services, which we offer through eInfochips, have led to the design and development of 500+ products. In addition to offering the best-in-class hardware design engineering services to clients in a variety of industries, eInfochips has a strong ecosystem of partners. Know more about our key offerings and services.

Application and Uses of PCB (Printed Circuit Boards)

Today, electronic components are connected through circuits on a PCB that serves as the primary functional center for most electronics. PCBs are used across a wide range of industries, and new applications are being discovered every day. With a variety of configurations and types available, PCBs offer flexibility and can be used in various applications and capacities.

Let’s explore these applications in more detail.

Medical Devices

A wide variety of electronic devices are used in the healthcare industry for diagnosis, monitoring, and treatment. The medical applications of electronic devices continue to expand as technology becomes more efficient and denser.

A PCB is at the heart of all these medical devices, but due to their unique constraints, PCBs used in the medical industry require a specialized design. An emergency room monitor or surgical implant typically requires a small package, which is why medical PCBs tend to be high-density interconnect PCBs, commonly known as HDI PCBs. There is a wide variety of flexible base materials that can be used in medical PCBs. The health implications of medical PCBs make them subject to higher standards, and their suppliers must adhere to stringent medical regulations while achieving repeatability and reliability.

Common Medical Printed Circuit Board Applications:

- Monitors: These measure blood glucose, heart rate, blood pressure, and other vital signs for personal use and healthcare.

- Scanning Technology: PCB electronics are commonly used in CT scanners and ultrasonic devices.

- Control Systems: Electronics control fluid flow rate, infusion rate, and dispensing.

- Internal Devices: Medical devices inside a patient that monitor their health using minuscule circuit boards.

- Scientific Instrumentation: To study diseases and assess patient outcomes, medical research uses a variety of scientific instruments. Additionally, other systems control generators, compressors, and photometers.

Consumer Electronics

Smartphones and computers, for instance, are consumer electronic devices. Even new refrigerator models include electronic components.

The number of PCBs manufactured to control these consumer electronics must be consistent due to high-volume production. Since these high-volume PCBs have a low per-unit cost, they keep the final product at an affordable price. The PCB industry must adhere to strict quality control and industry standards like IPC to guarantee the quality and uniformity of every consumer electronic. PCBs are extensively used in consumer electronics. Here are a few common applications:

- Mobile Devices: We use mobile devices such as alarm clocks, GPS devices, and everything else we need in our daily lives.

- Computer Electronics: PCBs are at the core of desktops and laptops, as are screens and peripherals.

- Recording Devices: All recording devices require PCBs to function properly, including camcorders, digital cameras, and microphones.

- Entertainment Systems: Every component of your home entertainment system, from DVDs to video games to televisions and stereos.

- Home Appliances: Electronic components are used in everything in our daily lives, such as microwaves, refrigerators, and coffee.

Industrial Applications

PCB’s high-power industrial applications are also common. These electronic components are used to control machinery in factories and manufacturing facilities, and they must withstand harsh conditions. Any type of hazardous chemical, vibrating machinery, or rough handling can be included in this.

Industry standards must be rigorous in such a fast-paced, challenging environment. There are several other applications for thick copper PCBs (significantly thicker than standard-ounce PCBs) now. Such PCBs are suitable for battery chargers and high-current industrial applications.

- Industrial Equipment: PCB-controlled electronics are commonly used in electric drills and presses in manufacturing.

- Measuring Equipment: Throughout industrial manufacturing, measuring equipment is used to measure, control, and record pressure, temperature, and other variables.

- Power Equipment: Power converters for converting DC to AC, solar panels, and control equipment for controlling power.

Automotive Application

Today’s automobiles incorporate many new applications in PCBs to take advantage of advancing electronic circuit technology. Most sensor applications in cars use high-frequency PCBs, such as RF, microwave, or millimeter-wave, to detect blind spots, maintain traffic conditions, and avoid collisions using radar technology.

Advanced driving systems are becoming more popular in vehicles as they enhance safety and the driving experience. Consequently, the manufacturers of these systems must source and use a higher volume of high-frequency PCBs.

PCBs are commonly used in automobiles for the following purposes:

- Surrounding Monitors: Newer car models come equipped with full-perimeter monitoring systems that use radar or cameras to measure distances and alert drivers to objects within a certain distance. PCBs are essential to the functioning of these systems, allowing drivers to monitor blind spots and judge distances accurately.

- Control Systems: PCB-based electronics monitor and manage resources to drive the car for the driver in certain situations. Some cars today offer automatic parallel parking, for instance.

- Navigation Devices: Modern vehicles have integrated navigation devices that assist drivers in finding their way through unfamiliar territory or determining the fastest route.

- Audio and Video Devices: Advanced dashboards in today’s cars allow passengers to connect their phones and music devices to the radio. Many family vehicles also feature movie screens to keep passengers entertained on long trips, all controlled by PCB-based electronics.

Aerospace Application

In aerospace applications, PCBs are required to be precise and durable, just as they are in automotive applications. A rigid PCB may endure enough stress to become damaged during a jet or a rocket’s atmospheric journey due to high level of turbulence that the jet or rocket experiences. This is why most aerospace manufacturers use flexible PCBs that are light, compact, and vibration resistant.

Besides being exceptionally durable, aerospace PCBs need to be extremely precise and high-functioning and manufactured for optimal functionality to prevent technical problems. Aerospace technology electronics must perform perfectly since they play a crucial role in the safety of vehicles and their crews.

The aerospace industry uses PCBs in a variety of applications, such as:

- Monitoring Equipment: The basic function of all instruments is to monitor and communicate with the ground control, including accelerometers, pressure sensors, microphones, torque sensors, and force sensors. Airplanes and rocket engines use these products to monitor their function and communicate with ground control.

- Testing Equipment: PCBs are used to develop and test aircraft and air vehicles. For the development of more effective, efficient, and safer aircraft, PCBs are used in structural, vibrational, and flight-testing equipment.

Lighting Application

The PCB provides a versatile platform for high-efficiency LED applications. The low-power consumption, high efficiency, and impressive light output of LED lighting solutions are putting them at the top of the list among a variety of industries. This LED’s versatility is further enhanced when it’s integrated with a PCB. PCBs permit LED lighting solutions to be applied to displays and indicators.

The lighting industry uses PCB LEDs for a variety of purposes, including:

- Telecommunications Industry: Lightweight and durable PCBs are preferred in the telecommunications industry to control LED indicators and displays in equipment due to the high concentration of machinery found within this industry. Aluminum substrate PCBs are often used in telecommunications lighting applications because of their better heat transfer properties than FR4 variants.

- Automotive Industry: PCB LED displays are commonly used in dashboard indicators, brake lights, and advanced panel displays in the automotive industry. Circuit boards for LED lights are particularly popular in the automotive industry due to their cost-effectiveness and durability, enhancing the value and longevity of vehicles.

- Computer Technology Industry: Aluminum-based PCBs are particularly popular for LED lighting in computers due to their heat-sensitive properties, which make them especially suitable for use as displays and indicators.

- Medical Industry: Medical applications, particularly surgical and emergency operations, require a high level of lighting, which can make it easier for physicians to see. PCB LEDs are the preferred lighting method in these applications due to the power and small size of LEDs. These applications are often built upon PCBs, specifically aluminum PCBs that are more durable and provide better heat-transfer abilities than other PCBs. Thus, PCB LEDs are a long-term solution for medical equipment that can be used repeatedly in several different situations.

- Residential and Storefront Applications: PCB LEDs are also becoming increasingly popular for residential and storefront applications, apart from being used as signs and displays in homes and businesses. Homeowners can light their homes efficiently with LED lighting at a fraction of the cost, while businesses can utilize customizable LED displays to advertise their storefronts.

Wherever electronics are used in the modern world, PCBs of all kinds tend to find applications. As broad and diverse as the market itself, PCBs have a wide range of applications.

eInfochips has also helped its clients who wanted to re-engineer their existing power meter system. eInfochips assumed full responsibility for the product redesign and development, leveraging Arrow’s market knowledge and supply chain to extend the life cycle by five years. To continue reading about the case study, click here.

Latest Printed Circuit Board Industry Trends

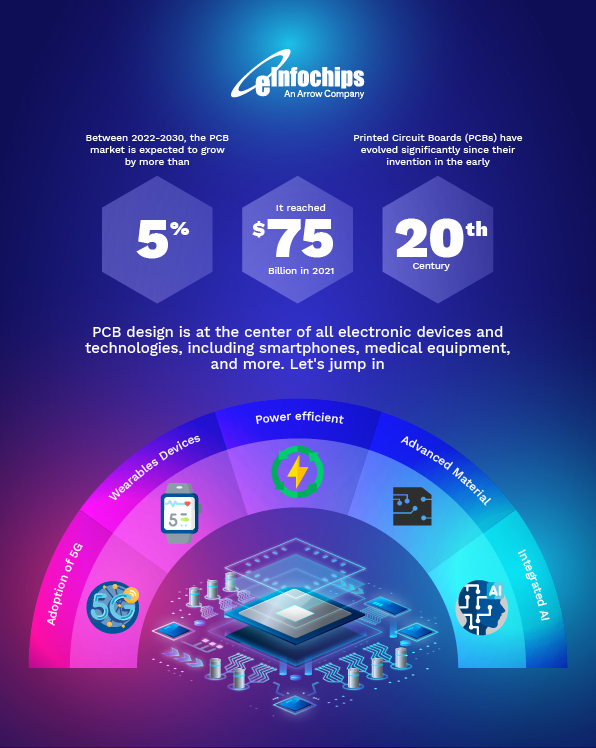

Between 2022 and 2030, the PCB market is expected to grow by more than 5%. It reached US $75 billion in 2021. PCBs have evolved significantly since their invention in the early 20th century. In the year 2024, several trends are defining the future of PCB design. PCB design is central to all electronic devices and technologies, including smartphones, medical equipment, and more. Let’s jump in.

- The Integration of 5G technology: Communication speed has been revolutionized by 5G networks, with 20 Gbps download speeds, 5G outperforms 4G and fixed-line Internet. Because 5G requires high-frequency transmissions, mixed-signal PCBs are necessary. These PCBs promote advancements across various industries by providing reduced latency and extended connectivity reach. One of the main trends in the PCB for the 5G industry is the use of small, densely packed circuit boards capable of handling high-speed signals without interference.

- Internet of Things (IoT): The Internet of Things has spread to industries like wearables, industrial automation, and healthcare. PCBs for IoT must abide by certain regulations. The ability to monitor and control home and office networks wirelessly has improved convenience. IoT devices can be small but functional, thanks to techniques such as Surface Mount Technology (SMT) that allows component installation nearby.

- Incorporation of AI for Intelligent Design: PCB design is being completely transformed by AI that makes intelligent and automated operations possible. AI systems can forecast possible problems, evaluate design specifications, and optimize layouts for economy and performance. Engineers can create the best circuit board designs with the help of ML algorithms that learn from previous designs and user preferences. AI-driven design tools also save time and resources by enabling quick prototypes and iteration.

- Miniaturization and High-Density Interconnect Technology: HDI (high-density interconnect) technology is expected to make significant strides in PCB design in 2024. By achieving unparalleled achievements in layer densities, these advancements have made it possible to integrate an incredible number of components into progressively smaller areas on PCBs. To reduce size without compromising functionality or reliability, designers are using sophisticated layout approaches including via-in-pad, blind and buried vias, and microvias.

- Flexible and Rigid-flex PCBs: Flexible and rigid-flex PCBs provide a lot of benefits when it comes to weight savings, design flexibility, space efficiency, control modules, lighting systems, sensors, and other automotive components. It can seamlessly integrate all the components with flex PCBs because of their ability to bend to intricate curves and geometries. High levels of performance and reliability can be maintained while developing lightweight and compact automotive systems, thanks to this integration.

- Enhancement of Thermal Performance: In PCB design trends for 2024, flexible material advancements have changed heat dissipation for high-power and small electronic device applications. These materials effectively move heat away from components and maintain ideal operating temperatures because of their improved thermal conductivity. By incorporating these developments, efficient heat management is ensured, reducing the risk of overheating and improving device dependability under tough circumstances.

To help you make decisions during the design phase of the PCB, material type, layout complexity, and prediction challenges that can impact the pricing of the product and the time to market, you can read more about the blog here.

Wrapping Up

As far as product functionality and device capabilities are concerned, the PCB industry has a bright future. A combination of fundamental concepts, cutting-edge methods, and a close watch on new trends is needed to master PCB design. We’ve looked at the key best practices, a range of applications, and the newest trends that will influence PCB design in 2024 with this guide. Being knowledgeable and flexible is essential for success in this fast-paced industry as technology advances.