DO-178B is the current de facto standard followed by aerospace companies in evaluating software considerations and meeting certification guidelines for their airborne systems and equipment. Since the 2010s, however, the focus is shifting towards a new guidance system – DO-178C – which represents a greater improvement over the former set of documents, offering benefits like long-term cost controls, compliance-based product development and improved visibility of future challenges and opportunities.

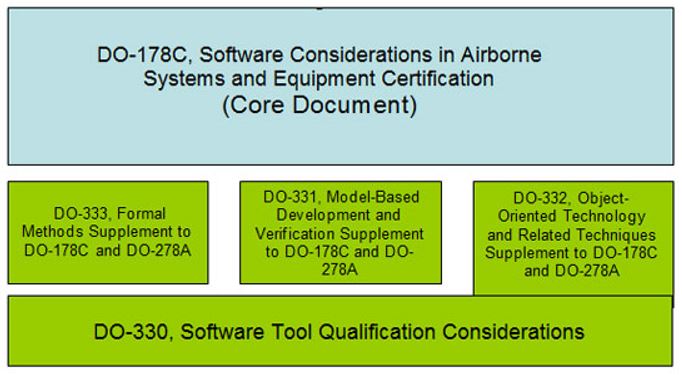

So, what’s new compared to the older version? A major chunk of DO-178C consists of minor changes such as removing known errors and inconsistencies, adding consistent terminology throughout the document, wording improvement and coordinated software aspects. It’s however the significant changes which merit our attention. These essentially consist of four technology supplements which have been added on top of core DO-178B to achieve the main aims of the new guidance system – robustness, security, stability and forward vision.

Accordingly, the added supplements are:

- DO-330: Software Tool qualification Supplement

- DO-331: Model-based Design & Verification Supplement

- DO-332: Object Oriented Technology Supplement

- DO-333: Formal method supplement

Here’s a brief explanation on why these additional supplements to the core DO-178B document are needed.

DO-330: Software Tool Qualification Supplement:

Automated tools are more reliable than human beings in performing certain types of analysis. Thus, the requirement was that SC-205/WG-71 should encourage the use of automation. Considering that the appropriate assurance could be obtained on what tools are as dependable as the manual processes that were to be replaced, this approach necessitated the development of clearer guidance systems to clarify the software tools. But, there was no reason to restrict these considerations to the airborne domain alone. A tool vendor could as easily apply a single qualification process to a tool that is universally applicable, resulting in a wider selection of tools with enhancement of tool quality. For these reasons, the concept of a DO-178C “supplement” would not be an appropriate guide for tool qualification. Instead, qualification guidelines are the subject of a new domain-independent document: DO-330/ED-215.

DO-331: Model-based Design & Verification Supplement

A long standing issue with RTCA DO-178B for practitioners of Model-Based Design is the uncertainty in mapping its objectives to Model-Based Design artifacts. DO-178C subgroup had focused mainly on Model-Based Design with the primary goal of addressing mapping. No single mapping sufficed, DO-331 addresses mapping of several objectives. It includes specification modeling but that approach is not typically followed in Simulink. Design models represent a more natural mapping for Simulink users. It is essential noting that one single model cannot be categorized as both a specification model and a design model, and this is explained in detail within DO-331.

DO-332: Object Oriented Technology Supplement

Object Oriented Technology was introduced in the aviation industry around 1999. The essence of this technology was first captured in OOTiA handbook. Object oriented technology is a way of developing software based on objects that need to be programmed. The example of an object could be a Black Box: it sends and receives data. The object entails both data (structure) and code (function). The programmer does not have any idea of memory mapping or the data making the whole thing difficult to trace.

Airborne software needs traceability for effective programming. For a long time, the aerospace industry did not look at using OOT (Object Oriented Technology). But, with the advent of reusable components which save a lot of time on programming, it was difficult to ignore their usage in avionics. DO-178C/ED-12C addresses the needs and qualifications of OOT and has added it as a supplement called DO-332/ED-217.

DO-333: Formal method supplement

Formal methods are mathematically-based technologies that can be applied in software development and verification. The mathematical basis of formal methods consist of formal logic and discrete mathematics. Formal methods are driven by the expectation that appropriate mathematical analysis can contribute to the correctness and robustness of a design. The formal method has been implemented as a supplement DO-333/ED-216.

OEMs need to modify their existing practices to accommodate the revised guidance. Although the benefits from the adoption of new technologies and tools will be important, expectations must be strengthened by proper vision of challenges associated with transition and early adoption of revision.

At eInfochips, we have written a whitepaper on Transitioning from DO-178B/ED-12B to DO-178C/ED-12C. To know on the step-by-step procedure on moving from older versions to the latest guidelines of DO-178C/ED-12C, this is a handy reference guide where we have distilled through hundreds of pages of comparison to represent the biggest takeaways of this migration. You can also email us at marketing@einfochips.com.