Automobiles have become our second home as we spend most of our time traveling between home and work. Automakers are trying to leverage the benefits of the latest technologies to provide a unique customer experience.

Having said that, today, automotive manufacturers are facing their greatest challenge of all time – survive or thrive. Due to the introduction of disruptive technologies such as electrification, connected cars, and autonomous driving, the production processes have changed drastically.

OEMs are required to produce both electric and combustion engine vehicles in the same facility, remotely monitoring & controlling production capacity, and training the workforce to adapt to new technologies and processes, all at the same time.

The automotive industry is among the early adopters of digital technologies such as autonomous cars, electrification, and connected vehicles. Automakers are equally excited to implement digital initiatives in a production environment to create differentiation and gain a competitive advantage. Technologies such as paint shop automation, weld digitization, parts & pattern identification, predictive maintenance, and paper-less processes are helping automate manufacturing operations.

In this blog, we will take a closer look at the problem areas and key factors driving the digital transformation in the automotive industry.

Key challenges faced by OEMs

According to a recent survey conducted by Capgemini Research Institute, 98 out of 100 automakers have already invested in and planned for digital factory initiatives. However, only a few of them have had concrete progress so far. Some of the main reasons for slower adoption are the piecemeal approach and lack of vision.

Here are some of the challenges limiting their growth and planned objectives:

- Higher downtime – minimizing the production downtime gets complex with the lack of detailed data on the production line performance and predictive maintenance for aging equipment.

- Data-driven insights – lack of automation and analytics tools to collect data from sources, analyze data for anomalies, and generate actionable insights.

- Lack of holistic approach – different groups working in silos such as body, press, paint, and assembly with their self-defined processes.

- Paper-based processes – increases chances of human error due to manual interpretation and adds delay in manufacturing and supply chain operations.

- Workplace safety – with large moving parts and a lack of proper safety mechanisms, workers often experience fatal injuries and fatigue.

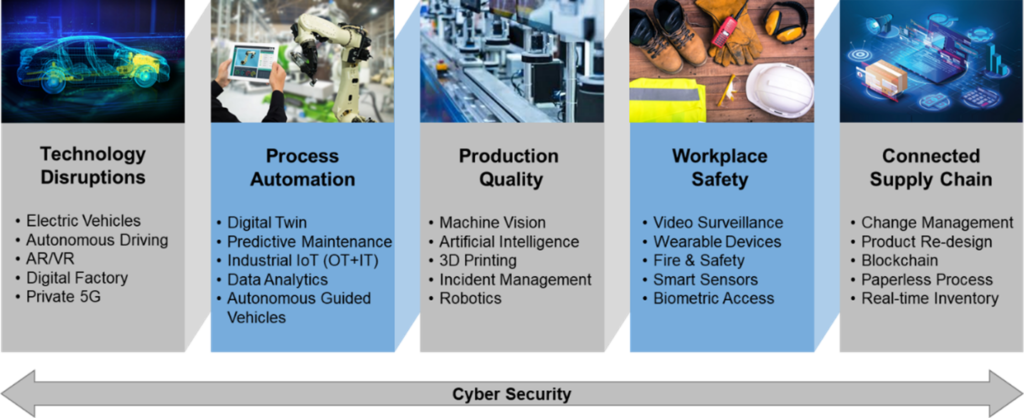

Key Drivers of Digital Transformation in Automotive Manufacturing

Mercedes Benz Factory 56 in Sindelfingen/Germany and Audi’s greenfield smart factory in Mexico are some of the real-world examples of smart factories realizing the benefits of digital technologies. In the following infographic, we have enlisted some of the key drivers of digital transformation across various functions in automotive manufacturing.

Let’s briefly discuss use cases of key technologies in automotive manufacturing:

Digital Twin

The digital twin is perhaps one of the most disruptive technologies being adopted by automotive manufacturers. Like virtual showrooms, where a user can take a digital tour of a vehicle’s features without a physical visit, Digital Twin enables manufacturers to design and simulate vehicles in a fully virtual environment. It helps in pre-commissioning of both product and production setup to demonstrate the impact of design changes, process improvements, and production efficiency. Some of the important use cases include:

- Detect product problems and find improvements well before they are produced.

- Shorten development and test cycles by virtually testing and optimizing processes.

- Generate data-driven insights by utilizing IoT, simulation, and predictive analytics.

Industrial IoT (IIoT)

IIoT is an integration of OT and IT, closing the physical-to-digital gap by bringing people, processes, and products together. It helps in making better decisions by collecting analog/digital data using IoT sensors, using advanced analytics algorithms, and generating actionable insights to increase operational efficiency. Predictive analytics and remote diagnostics are the most important application features of IoT in automotive. Some of the important use cases include:

- Track assets and reduce downtime using predictive maintenance of equipment.

- Analyze data gathered from production, processes, and supply chain.

- Utilize AWS/Azure IoT cloud platforms to remotely monitor and automate control.

Machine Vision

The key application of machine vision in manufacturing is to collect data in real-time and perform edge analytics using high-end camera systems and sensors. Machine vision also helps in monitoring workplaces for anomaly detection, site inspection, and efficient plant operation. Some of the important use cases include:

- Identification of products, parts, and repetitive patterns.

- Process compliance and quality control in an assembly line.

- Monitoring factories and warehouses for workplace safety.

Augmented and Virtual Reality (AR/VR)

According to research conducted by Deloitte, 22% of skilled manufacturing workers will retire by 2030. This poses a greater challenge for OEMs to keep investing in workforce training. AR/VR enables virtual experience and training for internal features of vehicle/equipment, helping a worker with limited prior knowledge or expertise. Microsoft HoloLens are such AR-powered smart glasses that provide self-guided instructions and on-the-job guidance helping workers to quickly learn complex tasks. Some of the important use cases are:

- Help solve the skill gap by providing virtual self-explanatory assistance.

- Reduce training times and increase worker productivity.

- Enable remote collaboration, technical support, and maintenance.

Automated Guided Vehicles (AGVs)

Besides the emerging autonomous technology for self-driving cars, AI-powered intelligent self-guided vehicles are becoming popular in automotive manufacturing. AGVs help in automating tasks such as moving inventory or materials on the shop floor and performing continuous operations with zero downtime. AGVs equipped with advanced sensors such as 360° cameras and LIDARs significantly help to avoid collisions and ensure safety for the workforce and products being transported. Some of the important use cases include:

- Eliminate manual and time-consuming process of material movement.

- Avoid fatigue and injuries related to repetitive tasks in the production environment.

- Reduce risk while working with heavy machinery and hazardous materials.

The way forward

Automakers like GM and Ford have many plants temporarily shut down due to the recent chip shortages, unavailability of skilled laborers, and lower operating margins as thin as 2-3%. On the other hand, new entrants such as Rivian and Lucid Motors are thriving due to their digital focus across the design-to-manufacturing value chain. New-age technologies such as AI, digital twin, autonomous, and robotics is reshaping the automotive landscape we haven’t seen before in many decades.

eInfochips – an Arrow Company, is a leading provider of digital transformation services for enterprises using cutting-edge technologies like cloud, analytics, UI/UX, mobility, machine learning, and RPA. To understand how we can help you in your digital transformation journey, contact our experts today.