Industries that use flammable materials like crude oil, carbon dust, and fibers are at risk of hazards due to fire explosions, in case of spillage of these materials in certain atmospheric conditions. These atmospheres which are highly prone to fires due to the spillage of flammable materials are called hazardous atmospheres. Hence, it is important to take effective hazard control measures. Considering the increase in the hazardous situations in different industries, the market for hazard control is estimated reach USD 1.63 Billion by 2022, at a CAGR of 5.83% every year, according to MarketsandMarkets.

When it comes to controlling hazards, several associations recommend following certain rules and processes to ensure the safety of industries. Utilizing Intrinsic Safety is one of the methods to control the hazards in the industries. Let us understand about Intrinsic Safely in detail:

What is an Intrinsic Safety?

It is a technique of design applied to electrical equipment and wiring for usage in hazardous industry locations. The Intrinsic Safety is a technique of limiting electrical and thermal energy to a level which cannot cause any hazardous situation such as fire spark due to a certain atmospheric condition.

Why is Intrinsic Safety required?

Intrinsic safety technique helps reduce the voltage and current so that there no enough energy to stimulate or spark an explosion.

There are basically two concepts to be understood while using the Intrinsic Safety technique.

- Intrinsically safe Equipment

- Intrinsically safe Design

Using #IntrinsicSafety technique can help reduce the voltage or energy that stimulate fire, preventing possibilities of fire explosions in industries

What is an Intrinsically Safe Equipment?

It is an equipment or wiring which is not capable of releasing enough electrical or thermal energy to cause ignition or spark at a location that has a hazardous atmosphere mixture under both normal and abnormal conditions even when it is in a highly-flammable form.

A mandatory requirement of operating electronic equipment in a hazardous area requires the usage of certified Intrinsic Safety devices.

Intrinsically Safe Design

There are lots of things to consider when designing an intrinsically safe product. Flammable gases, vapors, fibers, etc., can cause explosive hazards due to the spark or excess heat in the environment. This can lead to huge losses of property and even human lives.

So in order to deal with these problems, intrinsic safety (IS) standards are designed to reduce the risk of explosions in a potentially unsafe work location or environment.

The following are some design considerations for the initial planning of such products:

-

The Battery should be selected carefully:

The battery should be based on a high-density technology, which will be ainble to store a lot of energy. When selecting a battery for the use of intrinsically safe devices, the cells and batteries should be robust enough to withstand the hazardous work environment, as well as to minimize the amount of electrolyte leakage that can occur under severe short-circuit conditions.

-

Be aware of Published Electrical Ratings for Semiconductors:

The semiconductor components (e.g. Zener diodes) have a specific power dissipation capacity or rating, which is maintained in a data sheet. These ratings can vary with respect to a specific temperature. Often, the ratings in the components do not adequately reflect the conditions that the component will be exposed to in the end use application. So, it is important to understand and evaluate the effects that the end use application will have on the component’s power rating, thermal rise characteristics, etc.

BONUS BLOG

-

Protective Components Should be Selected Carefully:

Basically, circuits are designed to limit the amount of energy required for the spark ignition. Hence, it is important to choose components that have good operating and failure characteristics. Fuses, current limiting resistors, zener diodes are commonly used to design a powerful voltage and current limiting circuits that can be relied upon to maintain the energy and power limitation which is necessary for intrinsic safety.

How does an Intrinsic Safety Equipment Work?

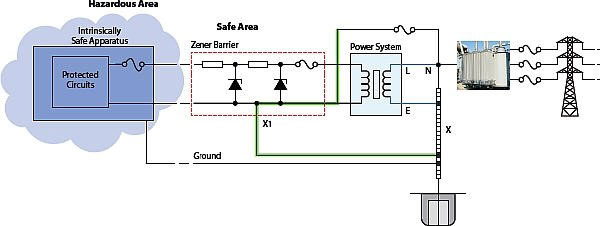

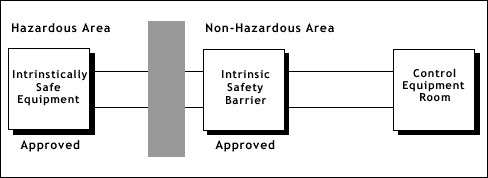

Most applications need a signal to be sent out of or into the unsafe area. The equipment applied in the hazardous area must first be approved for use in an intrinsically safe system. The barriers designed to protect the system must be applied outside of the hazardous area in an area specified as Non-Hazardous or Safe in which the hazard is not or will not be present.

Below is the figure which mentions, how the system works:

Usage

- Intrinsic safety equipment can be used in areas which have dangerous concentrations of flammable gases or dust a found in industries such as petrochemical refineries and mines.

- High-power circuits such as electric motorsor lighting cannot use intrinsic safety methods for protection.

Business Implications

- Intrinsic safety devices are used in the most hazardous zones of explosive environments. Incapable of igniting a spark, these intrinsic safety devices allow mobile communications at dangerous job sites, where traditional devices cannot be used.

- The hardware design of intrinsically safe Analog & Digital I/O and temperature modules are designed to absorb sparks created due to electrical spikes. Magnetic isolation was used instead of optical isolation for data transfer on I/O module.

- For troubleshooting and monitoring, Single-channel Remote Diagnostics are used.

DOWNLOAD CASE STUDY

Pros & Cons:

Advantages:

The advantage of using the intrinsic safety technique is that it is the only technique that is allowed to be used under Zone 0 of the IEC (International Electrotechnical Commission) Classification system for the hazardous area.

By using intrinsic safety, there will be no possibility of an explosion in the system.

Disadvantages:

It can be used for only low power circuits, thus it cannot have heavy duty intrinsically safe motors. So intrinsic safety is mainly used for only measuring and controlling instruments like pressure transmitters, control valve positioners, small capacity valves, etc.

Wrapping up

Intrinsic safe design technique helps prevent electrical equipment from becoming sources of ignition by limiting the sources of electrical sparks and high surface temperatures. Intrinsically safe devices, maintain the required separation distances when during the design and development of a new device or product to be used in a hazardous workplace. Intrinsic safety equipment increases the overall safety of the final product, which increases the level of protection of life and property in the hazardous operating environment. To know more how intrinsic safe devices and equipment are developed, download the case study Intrinsically Safe IO Module.